Our Revolutionary Process

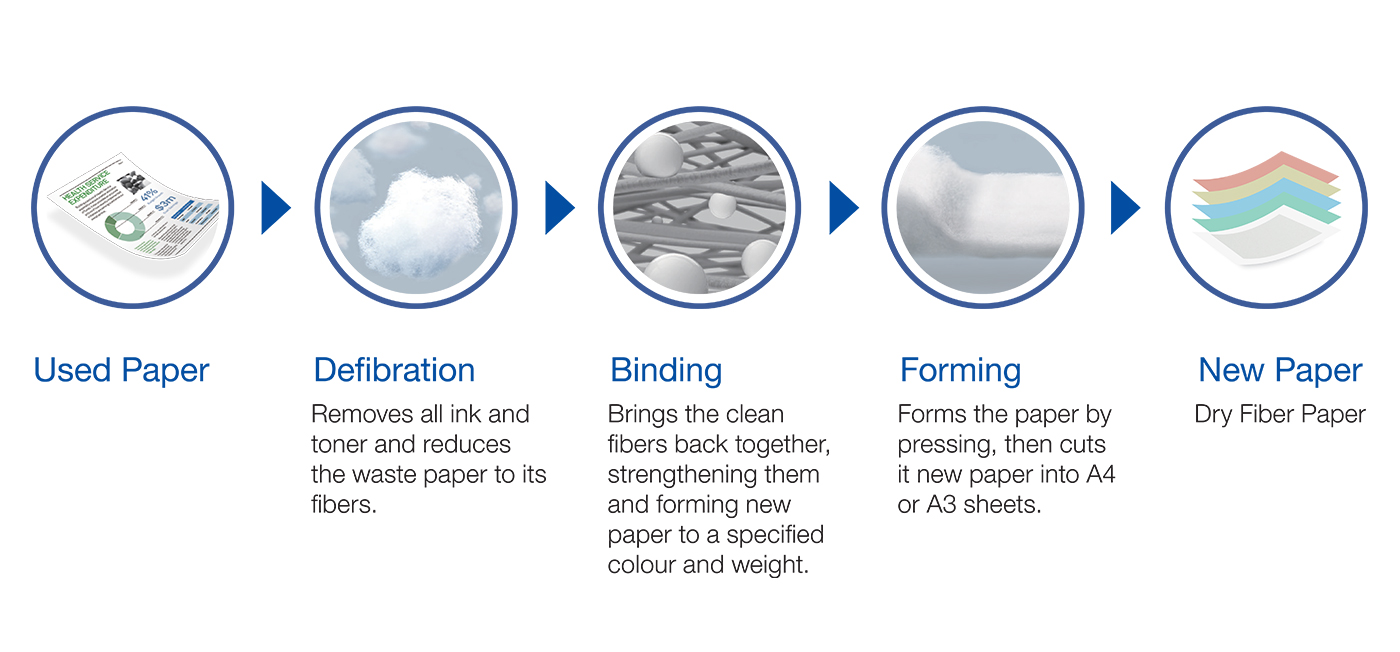

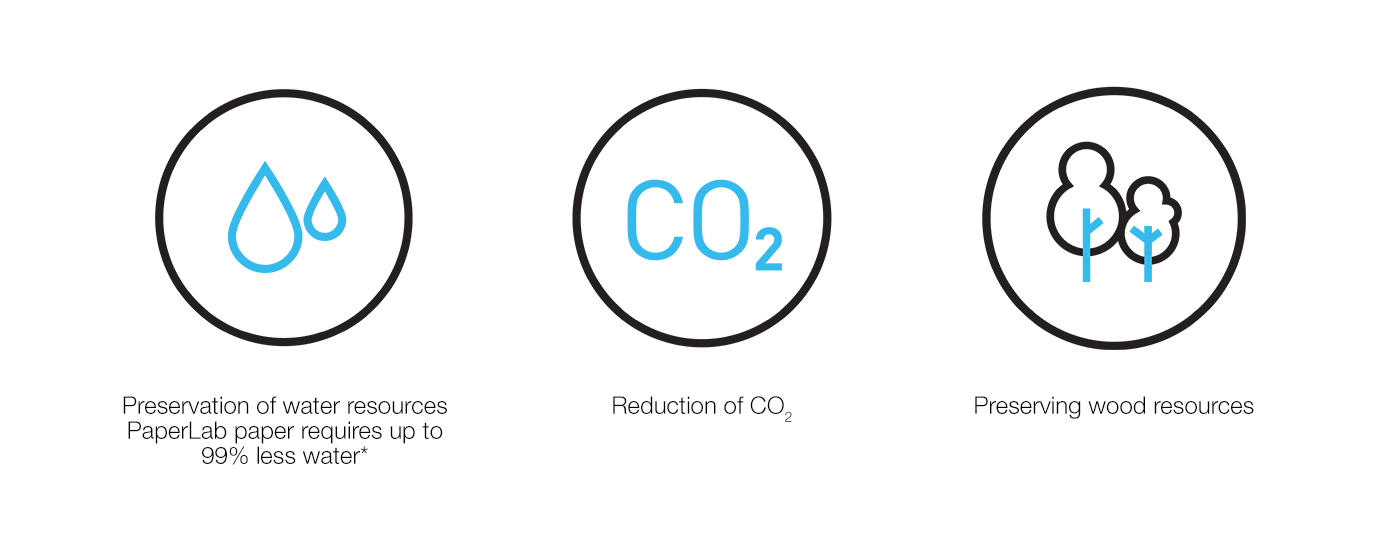

A combination of three processes is used to turn used paper into new paper – defibrating, binding and forming. Unlike traditional processes, PaperLab does not use water during the paper making process. This virtually dry process3 makes it possible to produce fresh, new sheets of paper in a small, localised cycle.

PaperLab uses Dry Fiber Technology to produce new paper from used paper through defibrating, binding, and forming processes.

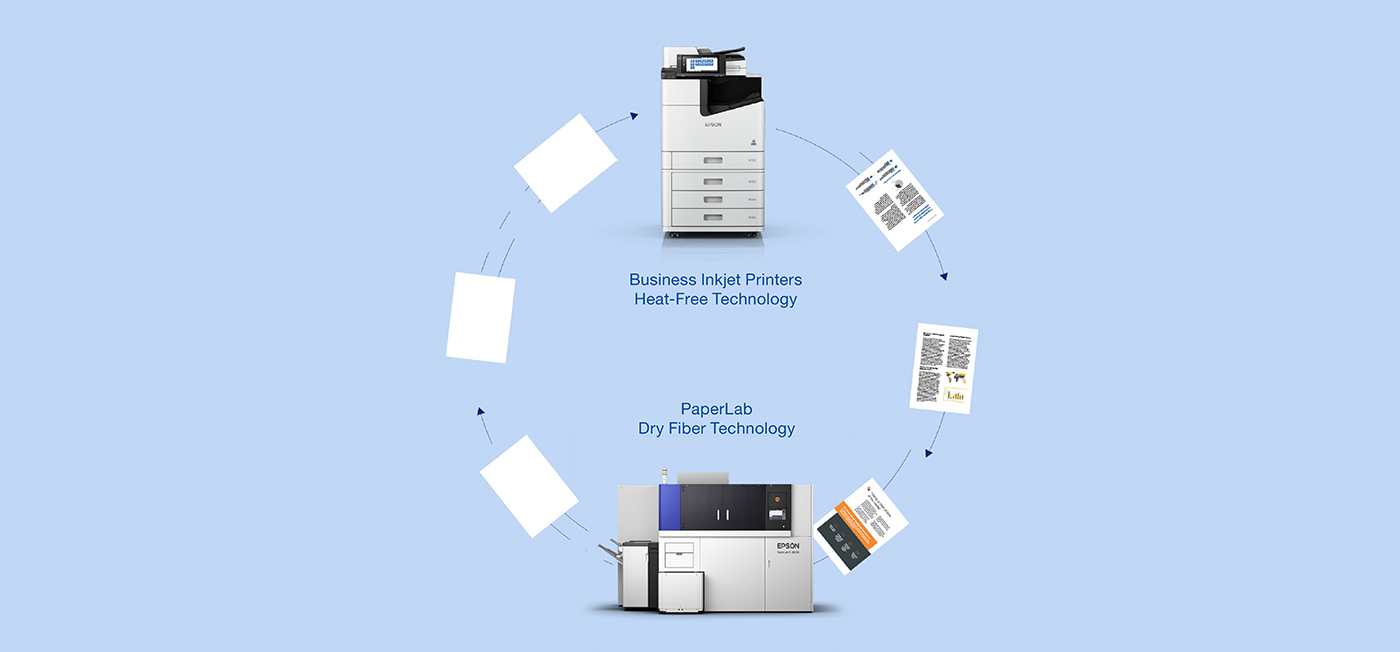

A new circular printing model to transform your office

By combining PaperLab with our Heat-Free Technology used in Epson business printers, you can achieve productivity and sustainability at the same time.

Contribute to a Circular Economy

PaperLab even goes beyond recycling, helping you upcycle and customise into different sizes, thickness and colours.

PaperLab can handle used paper in A4 or A3 sizes, and copy paper from 64g/m2 to 108g/m2.

PaperLab can produce up to 720 A4 sheets or 360 A3 sheets per hour4 after the first sheet has been produced, which equates to 5,760 sheets per 8-hour work cycle.

First sheet out time is 3 minutes4. The Dry Fiber Paper can then be used with ordinary laser printers, inkjet printers and copiers.

Destroy sensitive documents for complete certainty and security

PaperLab delivers absolute certainty that key confidential waste is safely and effectively destroyed. It removes toner and inks and takes the waste paper back to its fibers.

Your information stays safely on site and is never entrusted to external contractors.

This new solution goes way beyond conventional levels of information destruction, with a rating of P7.

ISO/IEC 21964-2 Security Level P7: Destruction of data carriers in such a way that the data on them cannot be reproduced with current technology or scientific knowledge (<5 mm3 particle size).

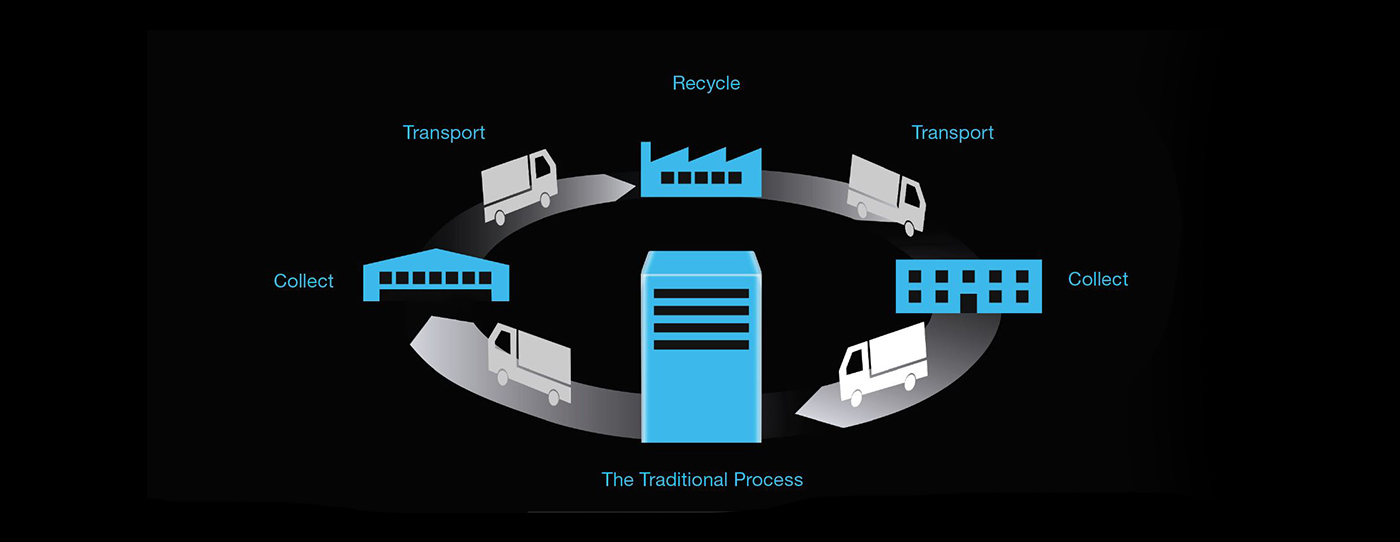

Out with the old, in with the new

The traditional process to destroy confidential office paper is by shredding. This involves bagging up the used paper which then needs to be collected or delivered to the shredding plant.

Shredded paper is only partially destroyed, despite undergoing a time-consuming process. It also needs to be processed and collected.

Disposing of used paper confidentially means using external specialists which can be expensive and result in a large CO2 footprint.

New paper must be sourced, purchased and delivered, requiring more planning and logistics and creating further environmental impact.

PaperLab in-house solution -small paper cycle

The used paper is collected or dropped off, then stacked securely in-house, ready for PaperLab. Within 3 minutes4, the new paper emerges from PaperLab (after the first sheet feeding has started).